At SOS Manufacturing, we specialize in wire harness and cable products, offering turnkey electro-mechanical assemblies as well as the capability to build one out utilizing customer-supplied components to best fit your application.

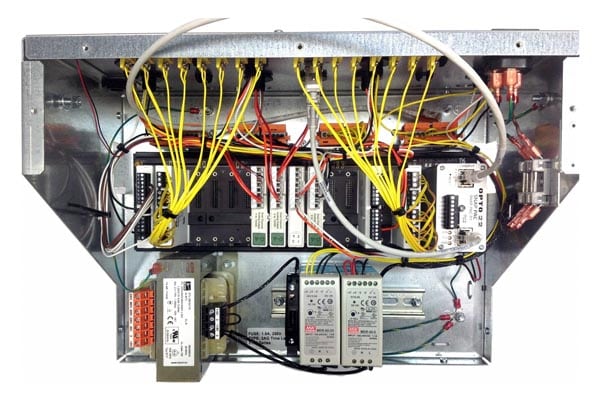

Electro-mechanical box builds and panel builds incorporate an electrical system’s wire and cable assemblies into box or panel housing enclosures so as to integrate and properly route subassemblies within. These builds have applications in downstream processes for the manufacturing sector, supplying power or electronic signaling to machinery or an overall system. With custom fabrication services, SOS Manufacturing can accommodate both simple and complex electro-mechanical assembly needs.

Electro-Mechanical Box Build Components

Box and panel builds typically consist of the following components:

- Printed circuit board (PCB). Manufacturers often construct electro-mechanical assemblies around a light and compact PCB that integrates the components. There is a wide array of layering options available for PCBs based on an application, starting at a single later, up to 60 layers for more intricate systems.

- Wire harness. Wires and cables carry predetermined loads of electrical signals from one component or subassembly to another in electro-mechanical assemblies. Harnesses provide organization for those wires and cables, bundling and organizing them within the enclosure.

- Electrical power source. The purpose of electro-mechanical box and panel builds is to supply power for system equipment. To do so, these assemblies will include a power source like a battery, generator, or outlet to supply the appropriate levels of current, voltage, and frequency to electrical components.

- Safety features. Manufacturers of electro-mechanical assemblies will typically design a box build with built-in safety features. These ensure that the electrical device is not only safe for use, but that operators can also safely shut them down. Such features might include sensors or switches for monitoring or slowing operations.

Manufacturers assemble electro-mechanical box and panel builds through a multi-step process. First, a technician will prep all components for the build and label any parts as necessary. Once they have all parts compiled and ready for use, the technician will proceed with building out any cable or subassemblies, wire harnesses, and more, testing the components before proceeding. If everything checks out, they will assemble the box or panel assembly itself, incorporating and installing the parts from the previous stage and connecting all wiring as needed. A technician will then test the overall assembly to ensure that it functions properly as a whole, can handle specified power loads, and more. They will also label all the inner workings of the assembly to aid in repairs or inspections down the line. At this point, technicians can proceed with software installation, configuring the assembly to incorporate that software. They will inspect the assembly a final time with the software to check that everything is fully operational.

Benefits of Electro-Mechanical Assemblies From SOS Manufacturing

There are quite a few benefits of outsourcing electro-mechanical box and panel builds to SOS, such as:

- Purchasing one component, not several. At SOS, our qualified technicians assemble your electro-mechanical boxes and panels for turnkey products, with customization available.

- Superior quality. We draw on decades of experience to build parts that optimize performance and produce manufacturing results so that your team won’t have to. By letting our certified technicians do what they do best, it allows you to better focus on your business.

- Supply chain simplification. SOS partners with a network of vetted sheet metal suppliers for dependable material quality and procurement.

- Competitive pricing. We maintain low overhead so that our business can offer competitive pricing. Also, by outsourcing your electro-mechanical builds to SOS, you can reduce your manufacturing and price-per-unit costs.

- Lower lead times. Our state-of-the-art systems allow us to provide on-time delivery to our customers, and we are always looking for innovative ways to improve our processes.

Applications

Our electro-mechanical assemblies have applications in a wide variety of industrial sectors. The following industries use these assemblies in box builds, industrial panels, power distribution units, fan tray assemblies, and circuit breaker assemblies:

- Aerospace

- Automotive

- Electronics and computers

- Energy

- Medical

- Military

- Security

Electro-Mechanical Box Builds From SOS Manufacturing

SOS offers high-quality box and panel builds, backed by over 20 years of industry experience in wire harnesses and cable assemblies. We are committed to superior workmanship, which is why our technicians are IPC/WHMA-A-620 certified, and SOS has both certified trainers and specialists on staff. We manufacture our durable products to provide customers with reliable performance, along with courteous customer service, competitive pricing, and prompt delivery.

At SOS, we strive to offer comprehensive value-added services for our worldwide customer base, including complete box builds and product assembly, custom fabrications, part kitting, CAD drawings and design, and engineering assistance. For more information, contact us today to see how we can help you with your electro-mechanical assembly.